For decades, the manufacture of Gyoza is based on a meticulous craftsmanship handed down from generation to generation. Every gesture counts: kneading the dough, preparing the stuffing, folding delicate and cooking But with the evolution of culinary technology, specialised machines are now capable of automate certain stages of the process, raising a crucial question: does the future of Gyoza lie with the machine or with man? Let's take a look at the advantages and disadvantages of these two approaches, and compare them. Man VS Machine.

Making pulp

La quality of a Gyoza is based first and foremost on its paste. It needs to be fine, supple and strong, to wrap the stuffing perfectly without breaking when folded. Its texture has a direct influence on the taste of Gyoza. If the pastry is too thick, its flavour will overpower that of the filling. On the other hand, if the pastry is too thin, it is likely to break during cooking.

By hand

In the Japanese traditiondough Gyoza must be prepared by an experienced chef. The chef must :

- Mastering dosing and kneading Mixing: the hot water, flour and salt must be mixed in the correct proportions. Kneading requires a great deal of force and consistency to ensure that the final texture is homogenous.

- Check thickness Each disc has to be rolled out individually, which is tedious and time-consuming, especially for large production runs.

- Managing variations Ensuring a uniform thickness between each disc is very difficult, which has an impact on the final result.

In addition to the time devoted to this preparation, it puts intense pressure on the joints and therefore promotes musculoskeletal disorders among chefs.

Using a machine

La Italgi noodle machine is specialised not only in making the dough, but also in rolling it out. It enables :

- A automatic kneading The machine mixes the ingredients evenly to give a homogenous result.

- A fast, precise lowering Its laminating cylinder produces perfectly calibrated discs of the right thickness for perfect Gyoza.

La Italgi machine frees staff from this physically demanding task, thereby reducing physical complaints.

👉 Winner: the machine - It radically transforms productivity while guaranteeing consistent quality.

Trimming and folding

These stages are the most technical and time-consuming in the making Gyoza. The amount of filling must be precise and the folding must be both attractive and airtight so that the Gyoza are resistant to cooking.

By hand

- A intuitive dosage The chef doses the stuffing by eye and according to his experience, which can create variations between Gyoza.

- A complex folding Traditional crescent-shaped folding requires dexterity and lots of practice.

For an experienced chef, folding can be done in just a few minutes. 20 seconds. However, it is difficult to guarantee a perfectly identical shape and size for every GyozaThis is especially true of high-volume production, where fatigue is a factor.

Using a machine

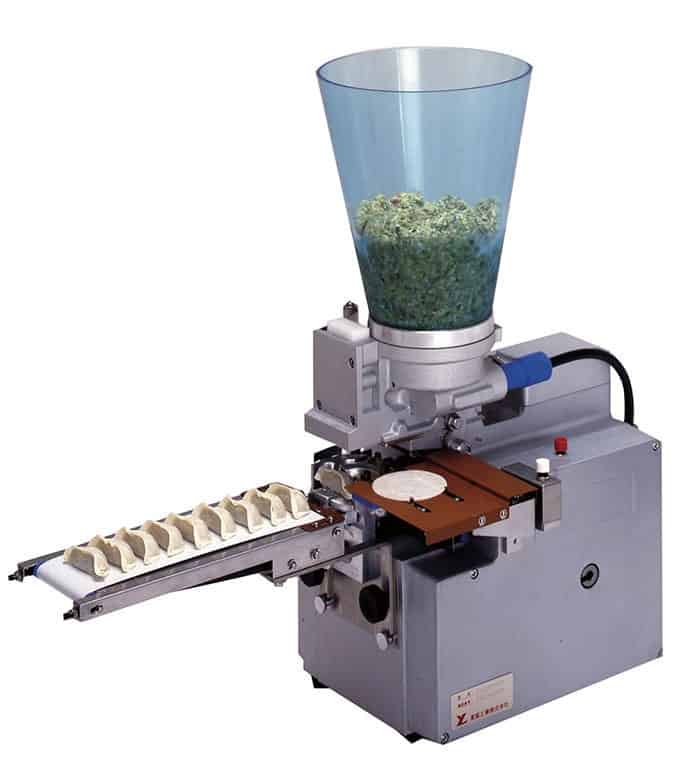

Machines specialising in the trimming and folding of Gyozasuch as MAG 1030are a revolution in the way these products are made. Japanese food :

- A precise automatic dosage With the machine, each Gyoza is stuffed with the same amount of filling, guaranteeing perfect proportions and less waste.

- A standardised hermetic seal the MAG 1030 ensures a perfect seal, greatly reducing the risk of opening during cooking.

- A speed of production With a productivity of 1,500 Gyoza per hour, the machine produces almost 20 times faster than man.

- A constant quality Each Gyoza has the same appearance and the same amount of filling, guaranteeing impeccable, professional presentation.

In addition to the time saving and qualityThe use of the machine frees up staff to carry out other tasks.

👉 Winner: the machine! - It revolutionises this stage by guaranteeing speed, precision and consistency that would be impossible to achieve by hand.

Cooking Gyoza

La cooking Gyoza requires a mastery of cooking times and temperatures, as well as traditional techniques. The "Yaki-Gyoza"(grilled gyoza) is characterised by being cooked in the three phases Grilled, steamed and then toasted to obtain its characteristic texture, crispy on one side and soft on the other.

By hand

La manual cooking on a pan presents a number of challenges:

- Temperature management The heat must be constantly adjusted to avoid burning the base of the gyoza, while ensuring that it cooks completely.

- Permanent surveillance The Gyoza must be constantly monitored to avoid cooking errors, which takes up the entire time of one member of staff.

- Irregular cooking Depending on their position in the pan during cooking, the Gyoza will not be cooked in the same way, creating variations.

- Capacity limitation A traditional frying pan can only cook a limited number of Gyoza.

Using a machine

Thanks to the DS 1302 Gyoza Grillcooking becomes a much simpler stage.

- Controlled cooking The grill allows you to regulate the temperature so that it is ideal throughout the cooking process, and is capable of delivering the right amount of water for each stage of cooking, depending on the recipe.

- Even cooking The position of the Gyoza does not affect the cooking process.

- High production capacity : in the Gyoza grill DS 1302Up to 48 Gyoza can be cooked simultaneously.

This machine makes it possible to offer Perfectly homogeneous gyoza and free up staff who were completely dedicated to this task. All this, while respecting the traditional technique of cooking Gyoza.

👉 Winner: the machine - It ensures perfect cooking and frees up precious time for serving.

If machines are revolutionising the production of Gyoza by guaranteeing speed, precision and productivity, they do not replace human expertise. The role of the chef remains essential for :

- Creative recipes : Developing new fillings and flavour combinations

- Quality control : Taste validation and seasoning adjustments

- The final presentation : Dressing and accompaniments that make all the difference

- Customer experience : Advice and adaptation to customer tastes

By combining traditional know-how with modern technology, professionals can offer Gyoza of impeccable quality while optimising their yield. The machine doesn't replace the human being, it assists him and allows him to concentrate on what's essential: the art of cooking and customer satisfaction.

For chefs and restaurateurs wishing to deepen their mastery of traditional Japanese techniquesthe Japanese Cuisine Academy offers dedicated training courses for professionals. Supervised by experts, these courses teach the precise gestures, specific cuts and fundamental principles of Japanese cuisine, while respecting traditions. A real asset for perfecting your skills and offering your customers an authentic experience.